Inside cilinder head

Air cleaner dome needed some hammerwork

Turned out OK

Reworked exhaust valve and new guide

I made a hand cranked tool to cut the exhaust valve seat

Cutting the exhaust seat

Intake valve and guide

Intake valve seat is easier to cut

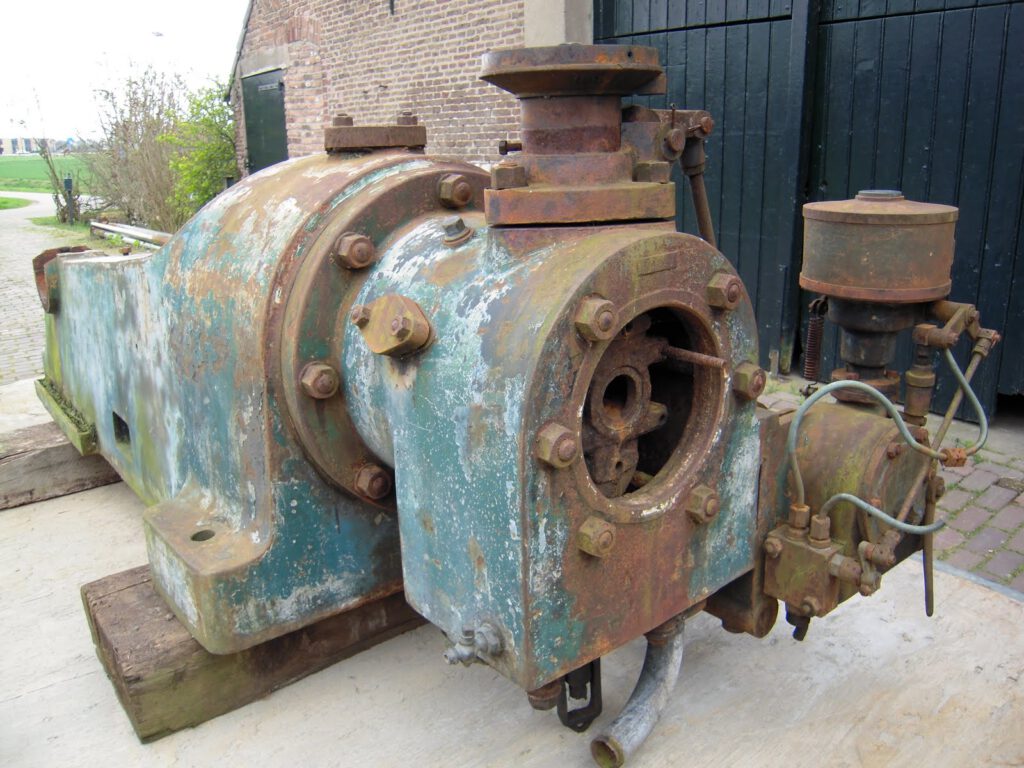

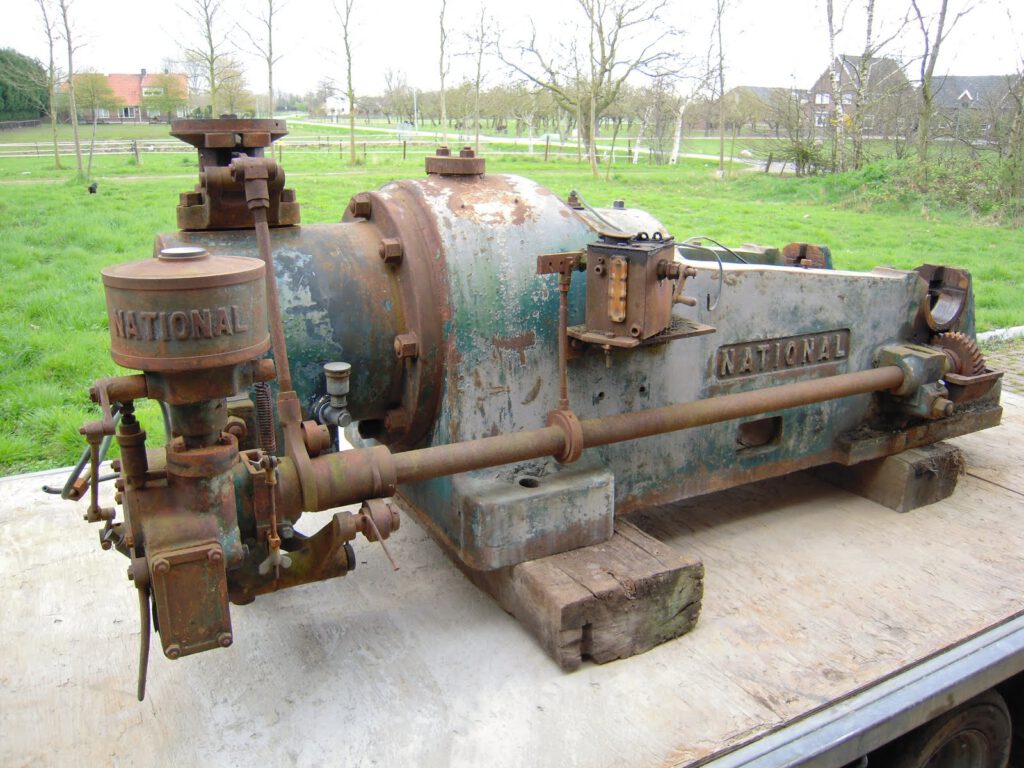

Turning a new cilinder liner

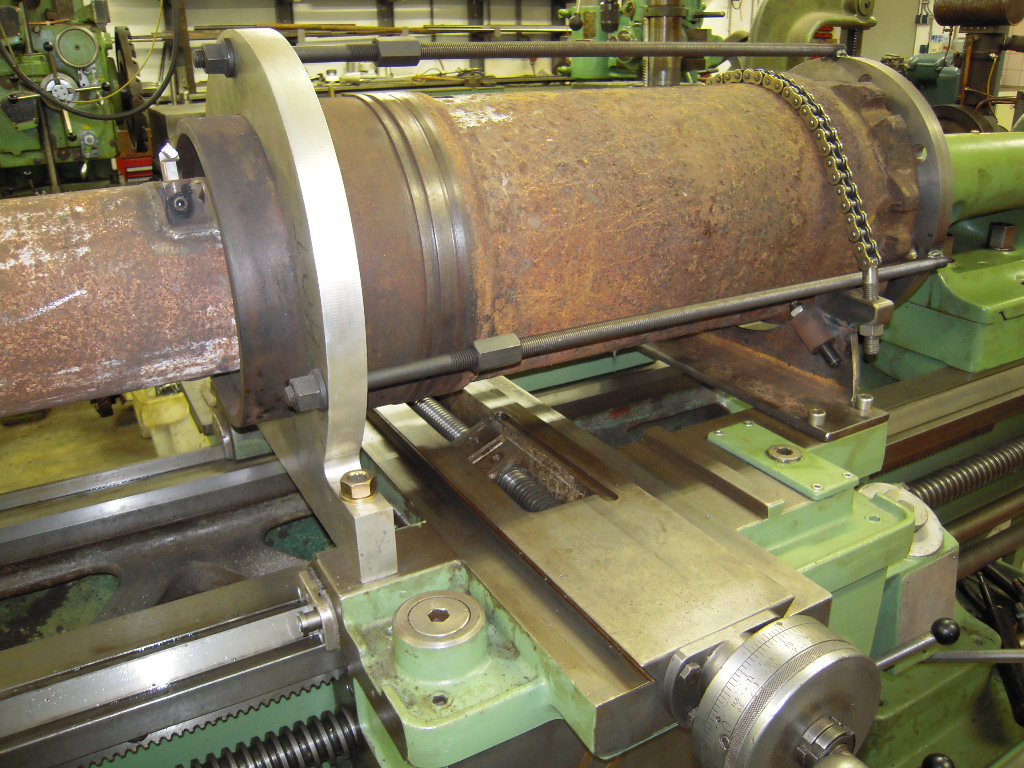

Boring the cilinder to receive the new liner

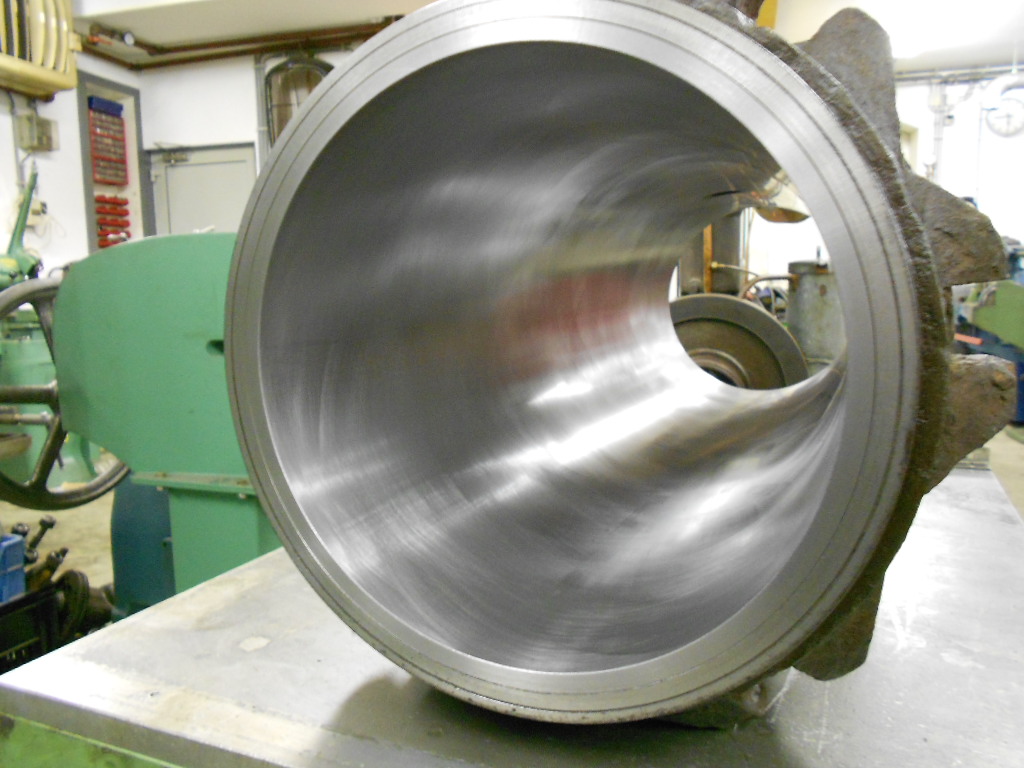

Boring the installed liner

Honing the new cilinder

Finished cilinder

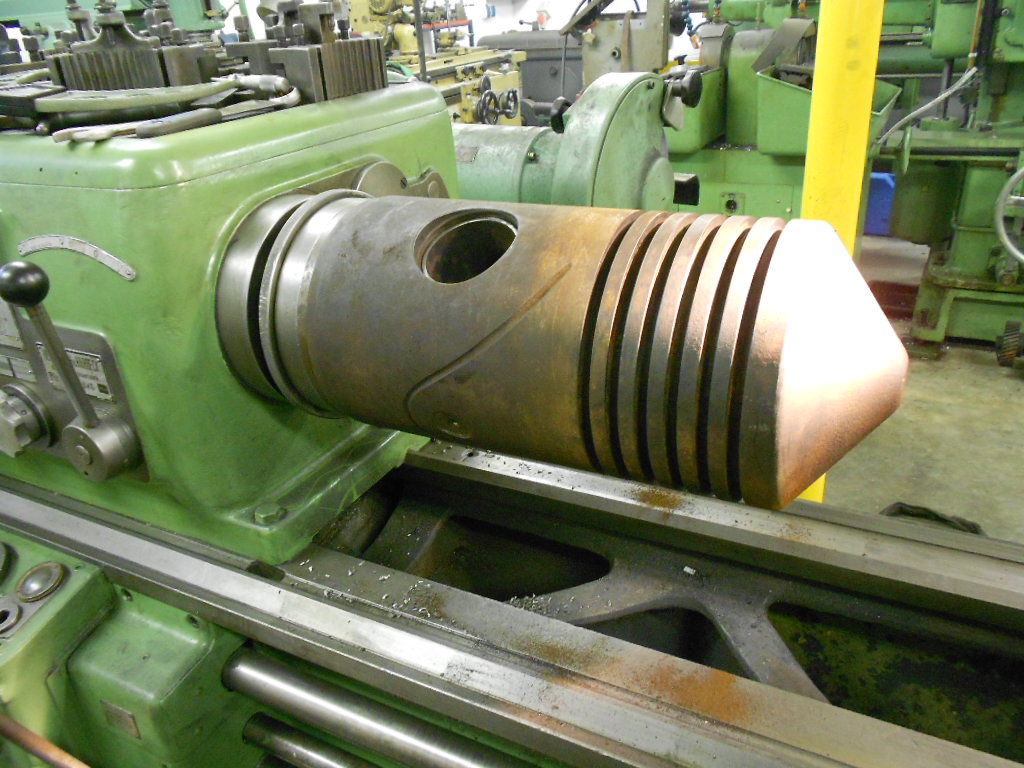

Piston in the lathe to remachine skirt and ring grooves

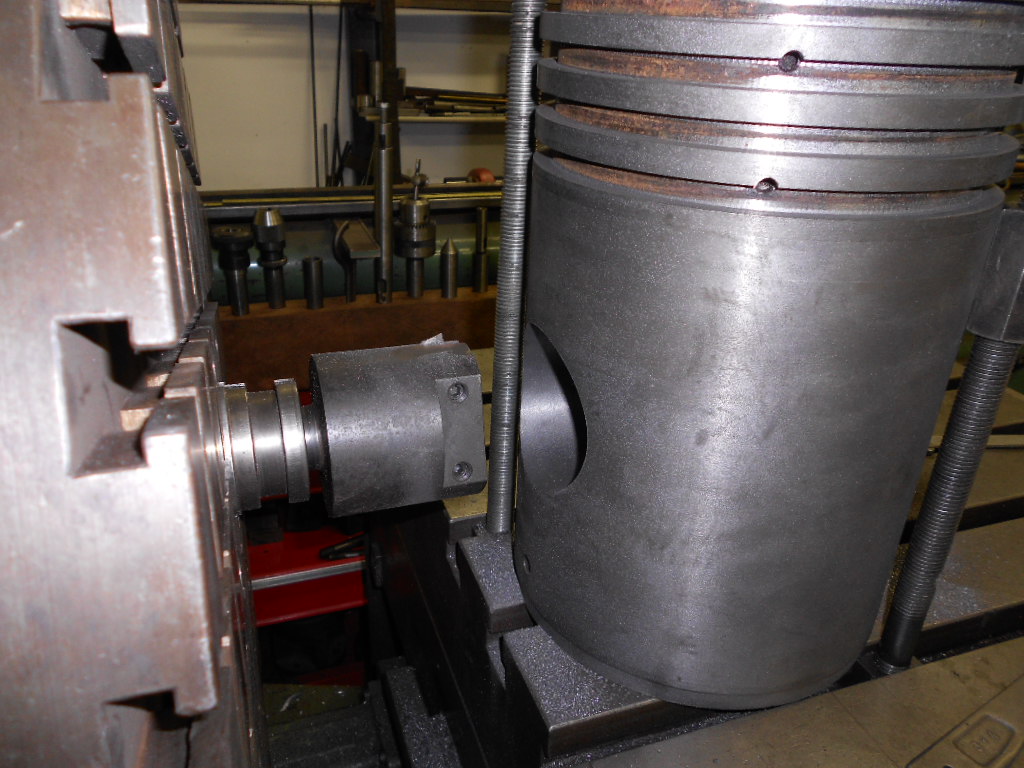

Boring the piston for a new piston pin

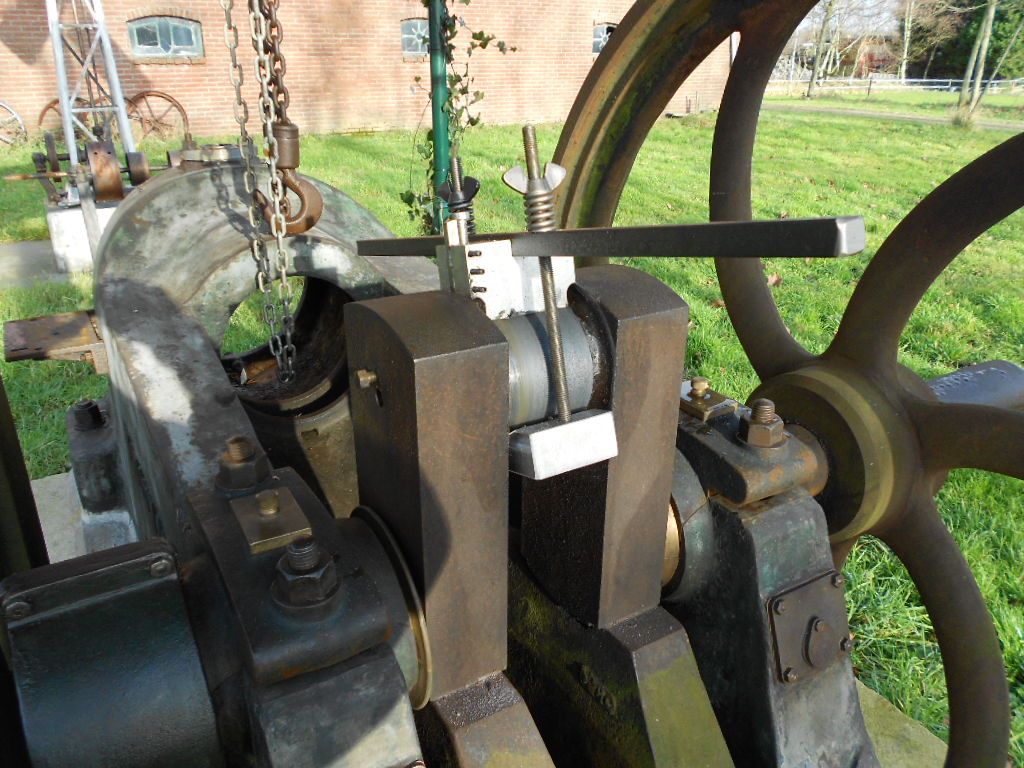

Tool I made to machine the crank journal in situ

Machining the crank journal

Tool to cut the journal radius

Hand cranking the radius tool

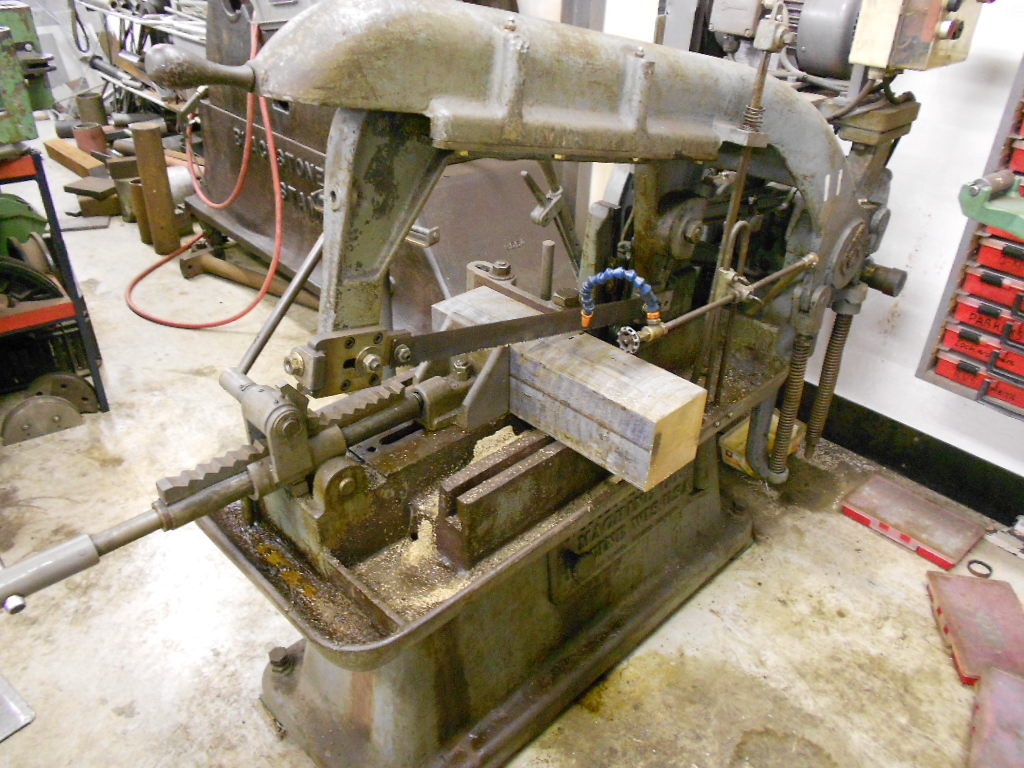

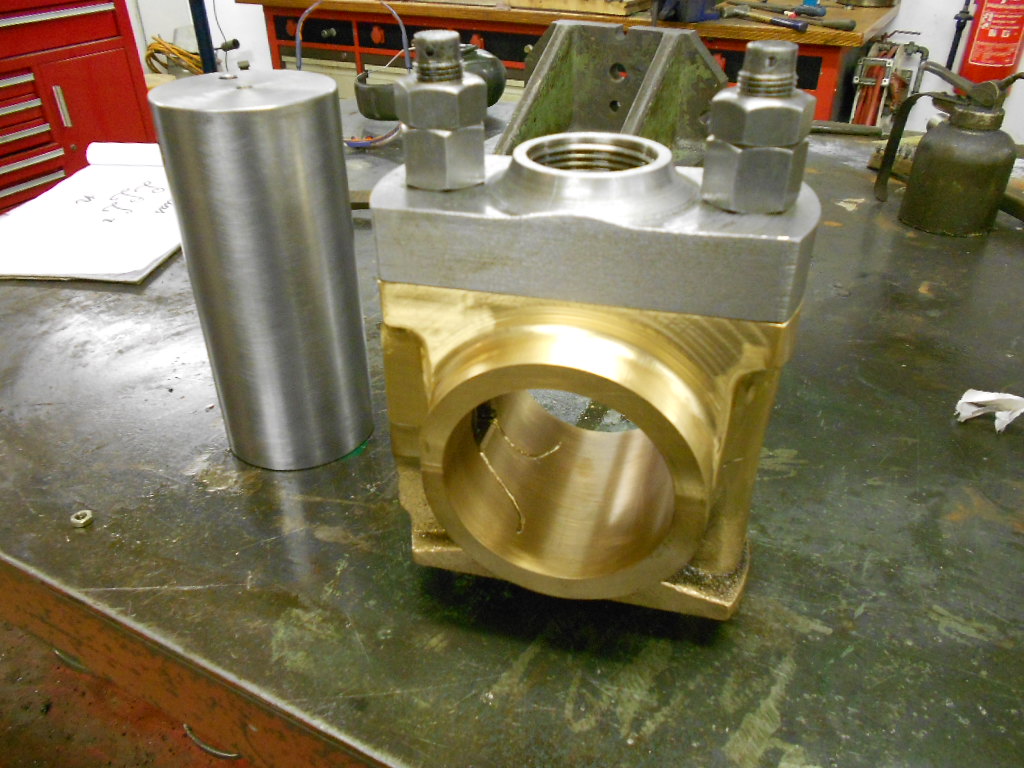

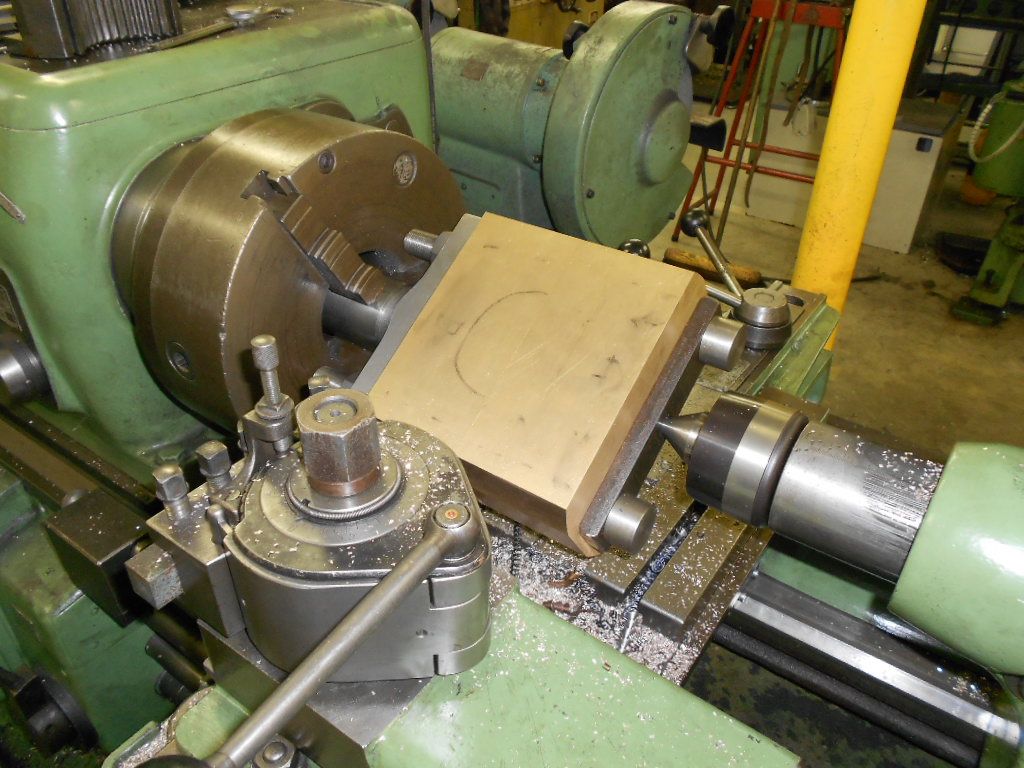

Parts to become the new connecting rod

Bronze stock for new rod bearings

Small end bearing and piston pin

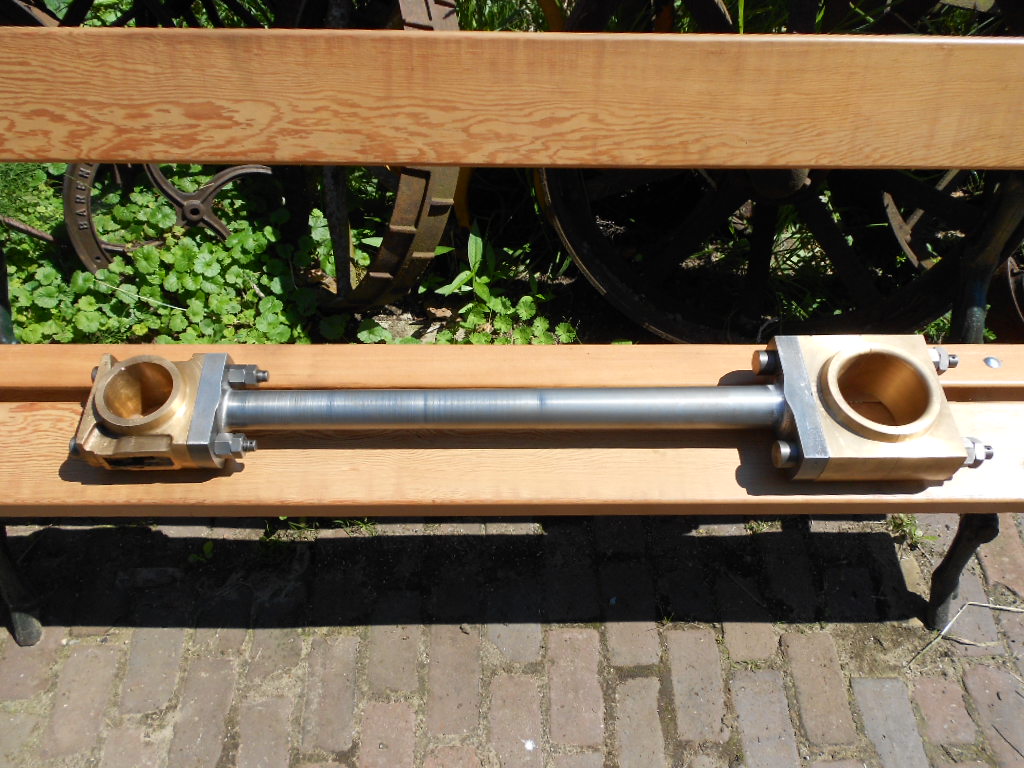

Finished connecting rod

The only original part is the top half of the small end bearing, all the rest was missing

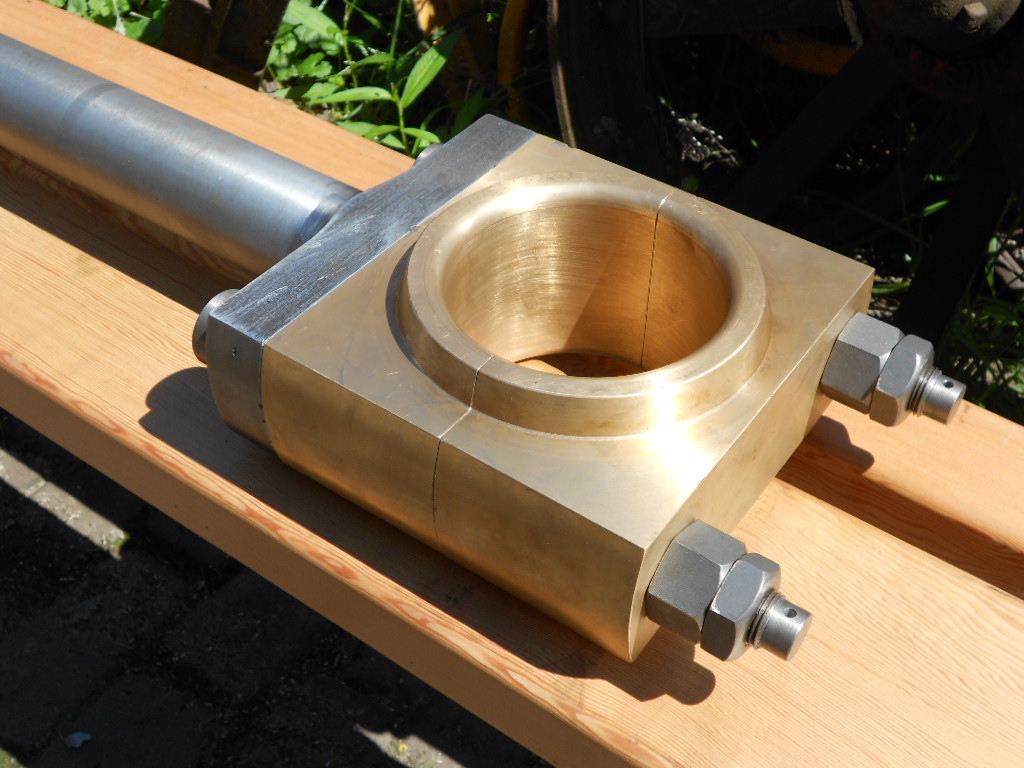

Big end

New cilinder head bolts

Cilinder head and cilinder assembly ready to install

One of the cam lobes was cracked so a new one was made